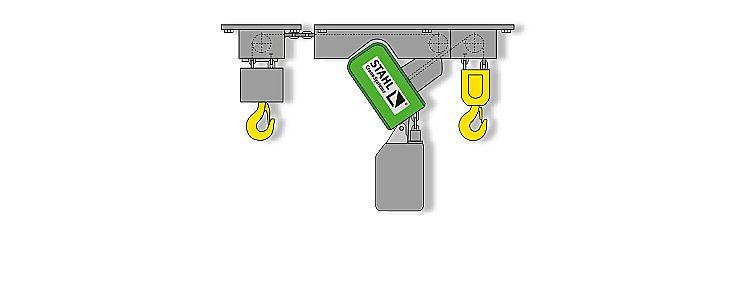

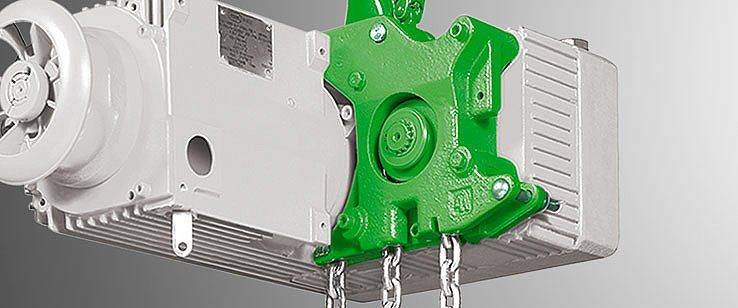

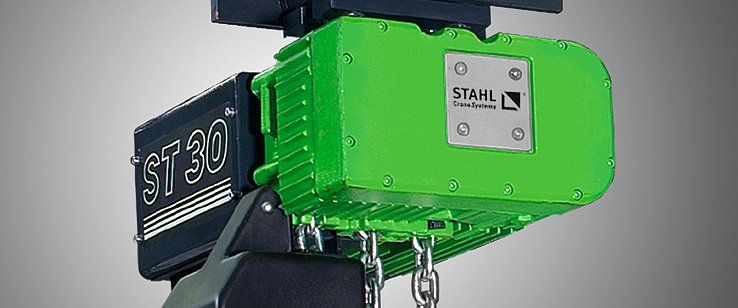

STD Dual Chain Hoist

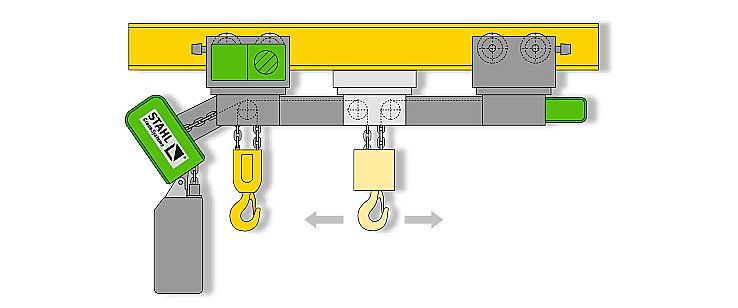

Safe Transport Of Long Loads

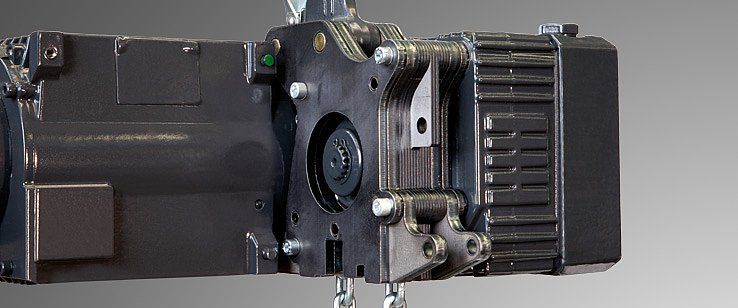

The STD dual chain hoist was developed specifically for long material and loads that need to be picked up at two points. It is equipped with two load chains, which are moved synchronously by a hoist motor. The hoist hooks spacing can be selected at will in dependence on the material being transported. The two synchronised rope lead-offs lift and transport the load without dangerous slant by design.

The two load hoist hooks work absolutely safely and in sync even in the case of materials of different lengths or uneven loading. Thanks to its low headroom, the STD dual chain hoist is also suitable for low buildings and achieves maximum hook paths with reliable hoist hooks.

The chain hoists are also available in explosion-proof design for Zone 1, Zone 21 and Zone 22.

- Low space requirement permitting maximum height of lift

- Two hook lead-offs running in synch on one hoist

- Synchronous lifting even with uneven loading, no tilting of the load

- Individually adapted to width of load

- Low maintenance

- Optionally available in explosion protected design complying with ATEX and IECEx

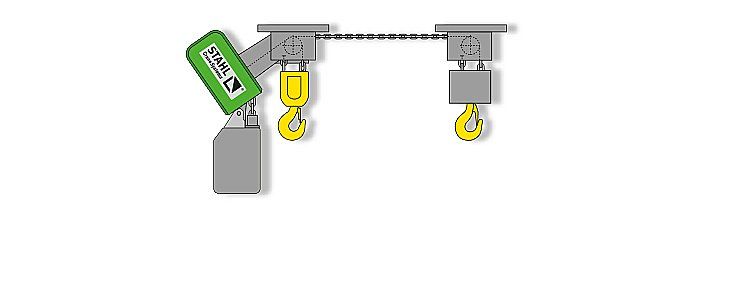

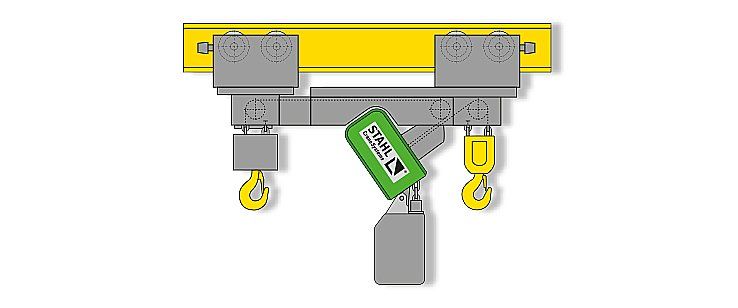

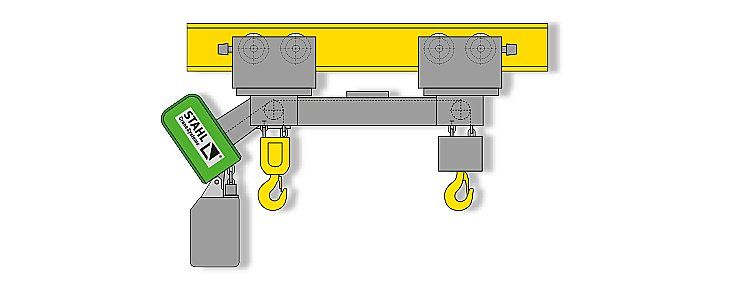

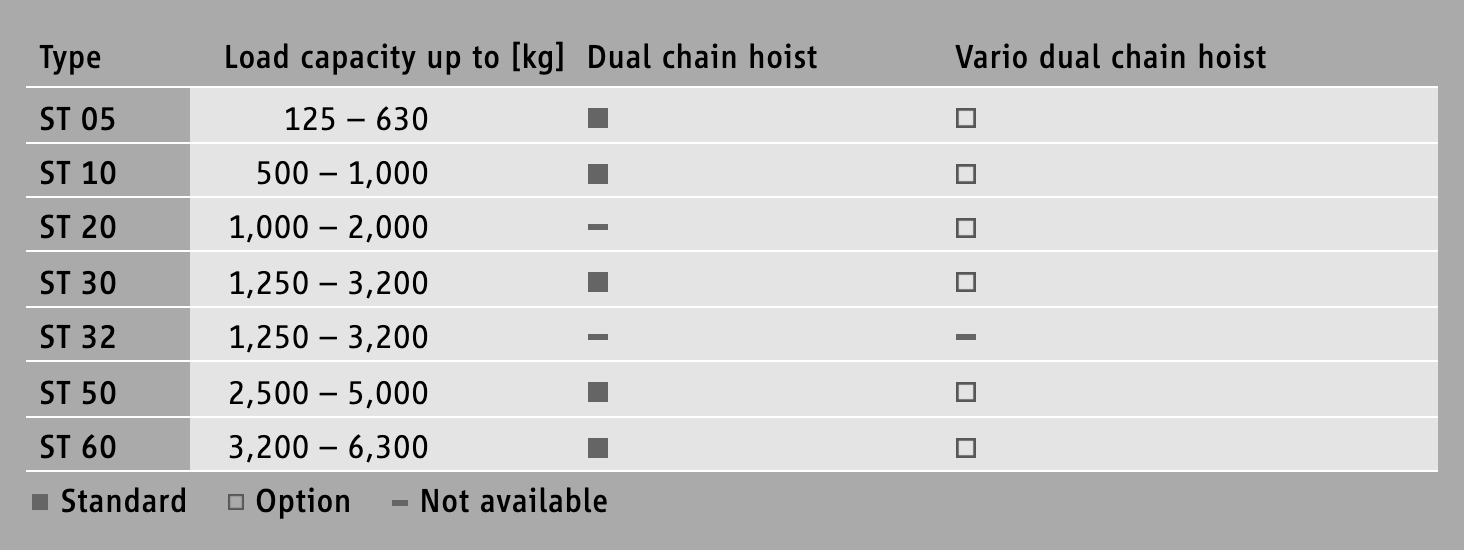

Models

The different models and trolley variants allow not only a wide variety of uses, but also very individualised solutions tailored to specific requirements.

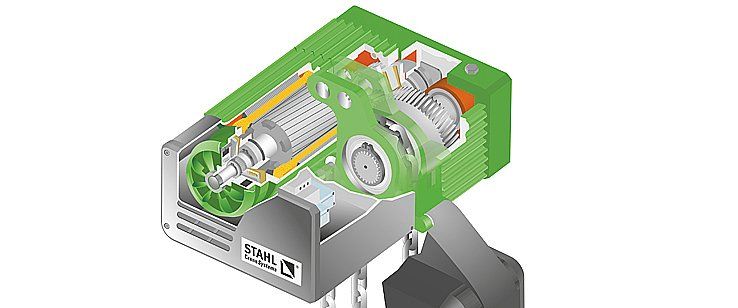

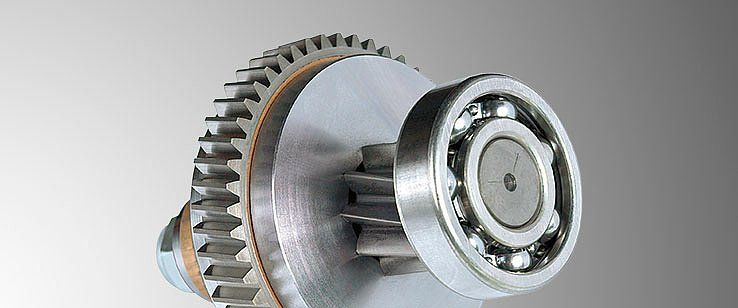

Technology

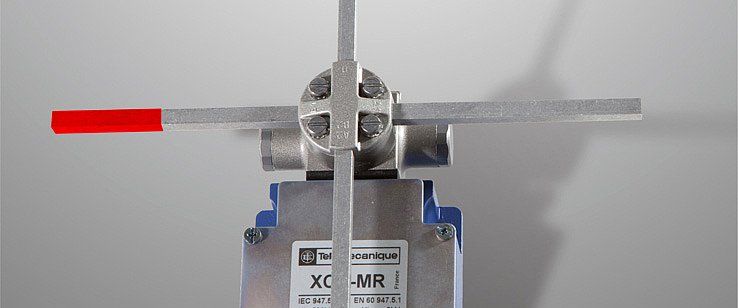

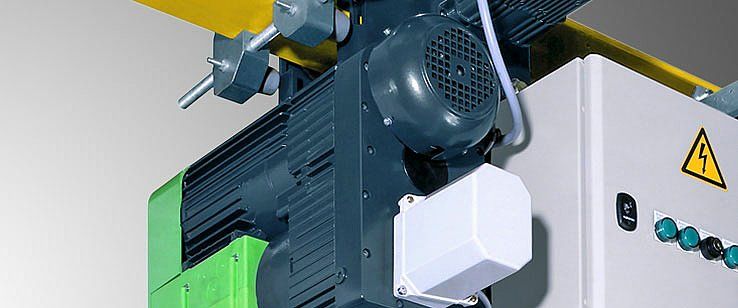

Options and features

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.