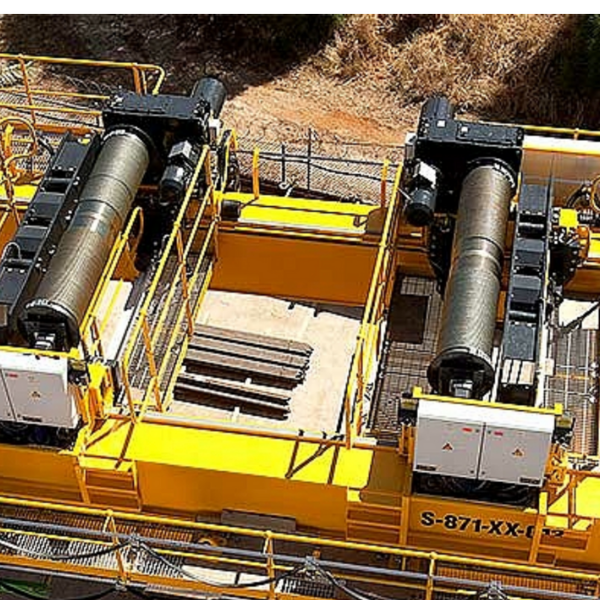

SHW 8 winch

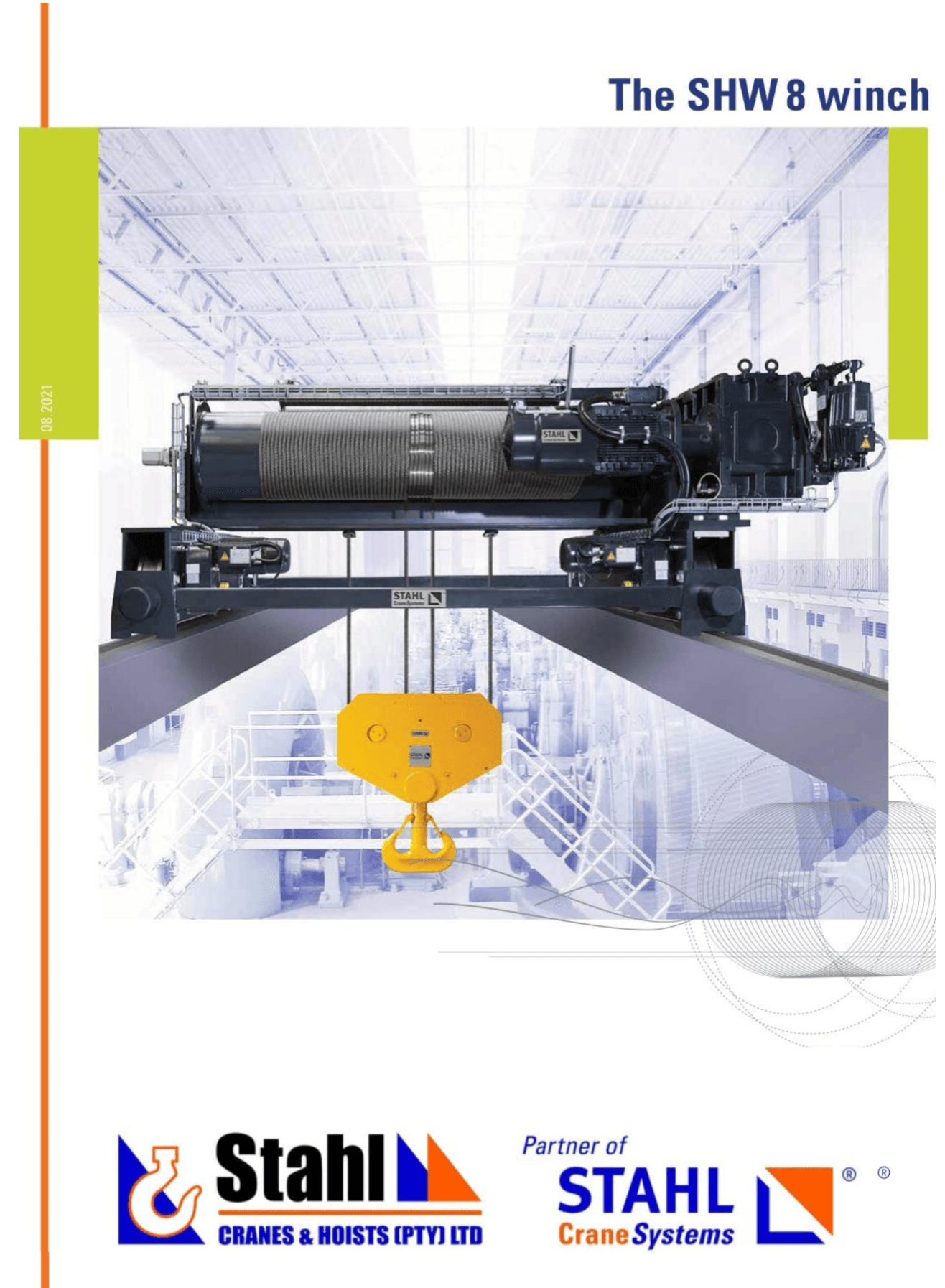

Top Technology For The Heaviest Of Loads And High Demands

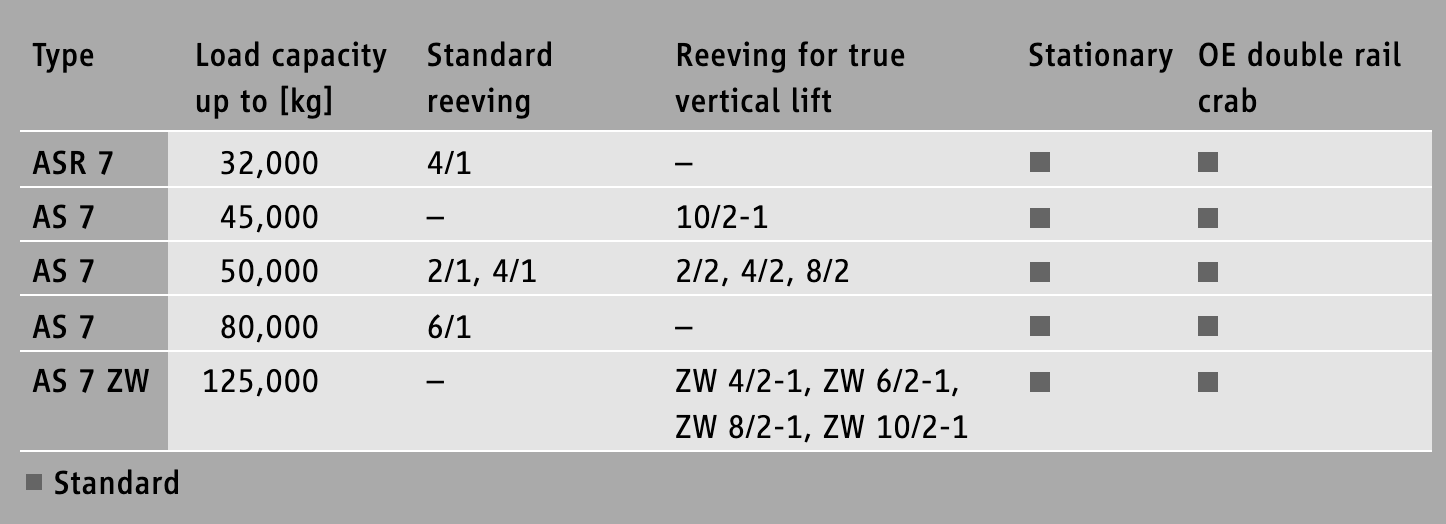

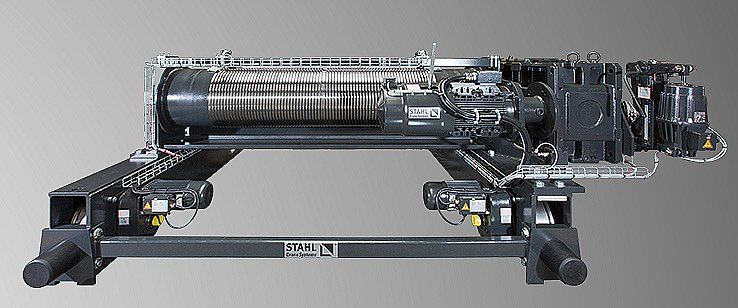

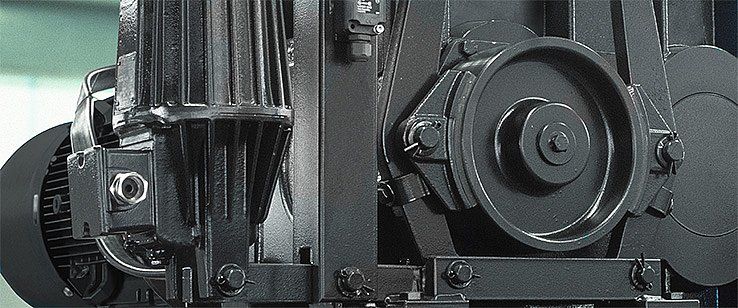

The SHW 8 winch program is based on the tried-and-tested SH wire rope hoist program and is designed for the high-load bracket up to 160,000 kg.

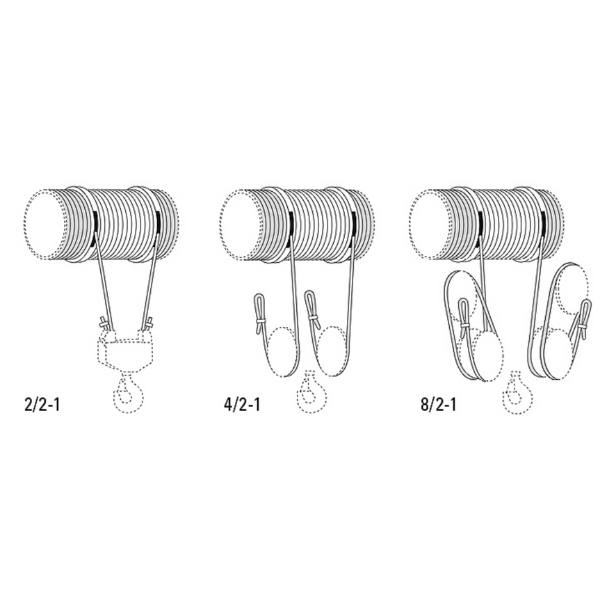

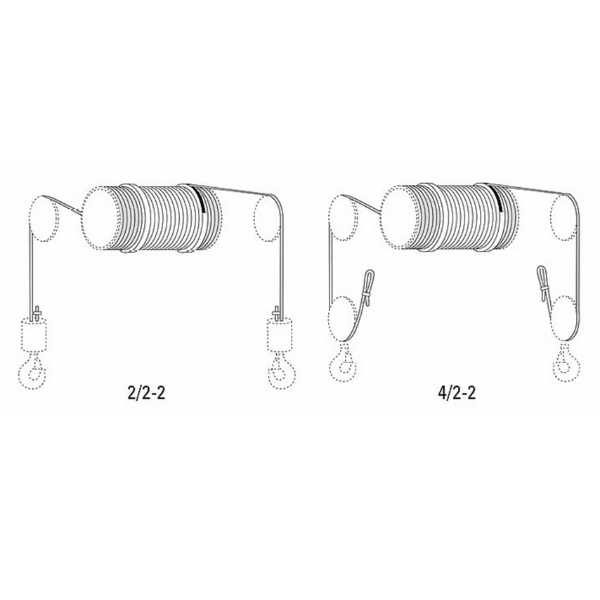

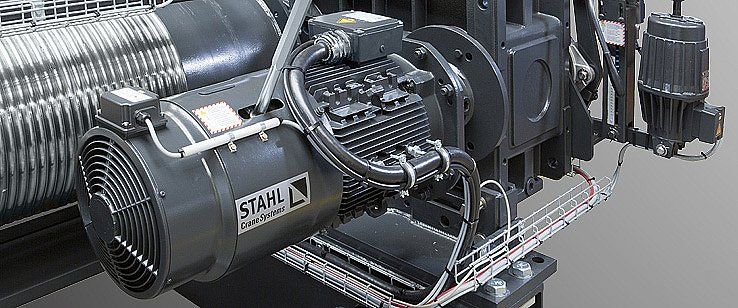

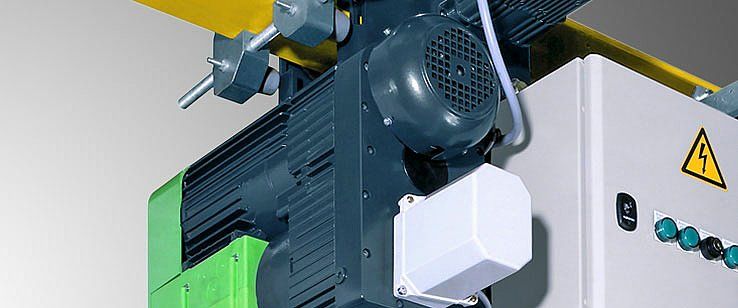

Its strong hoist motors and robust, low-maintenance design make it ideal for tough everyday use. Compared to wire rope hoists, winches only need a few rope reevings even for high loads, making a very compact construction possible. To enable a variety of different economical solutions, there are three motors up to 38 kW with two speeds in a ratio of 1:6 available for the SHW 8 winch. For higher ease of use, there are six hoist motors up to 98 kW with stepless speed control. All travel drives are equipped as standard with soft start. The SHW 8 winch is available on request with high-performance frequency inverters or with individually adapted speeds.

The winch programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

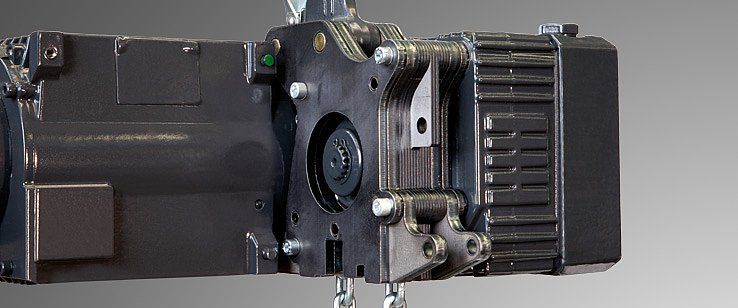

- Series components from the SH range, field-proven in thousands of applications

- Modular design for cost-effective individual solutions, simple transport and speedy erection

- Versatile drive technology meets demanding specifications: 3 hoist motors up to 38 kW with two speeds in a ratio of 1:6 and 6 hoist motors up to 98 kW and stepless speed control

- All travel drives with smooth starting characteristics

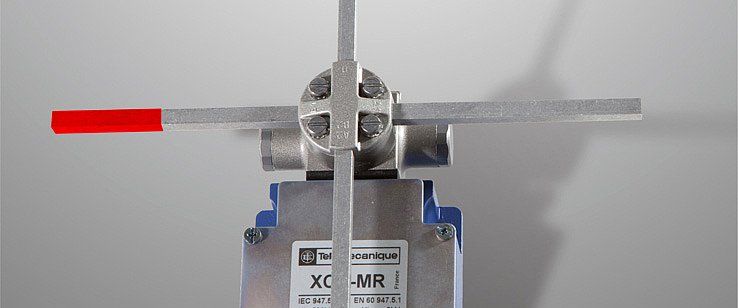

- Overload cut-off pre-set during manufacture

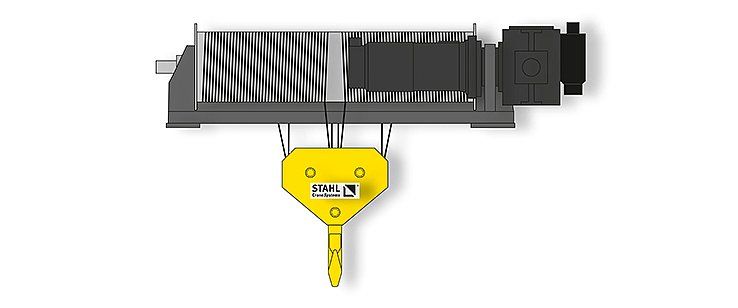

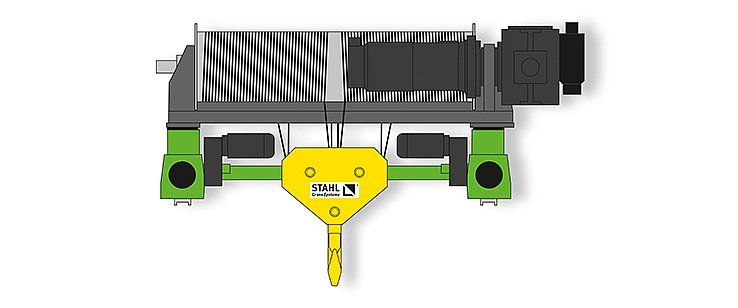

- Compact headroom thanks to innovative rope drive design

Technology

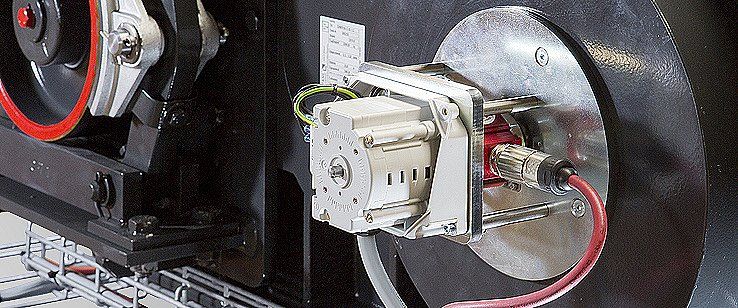

Options and features

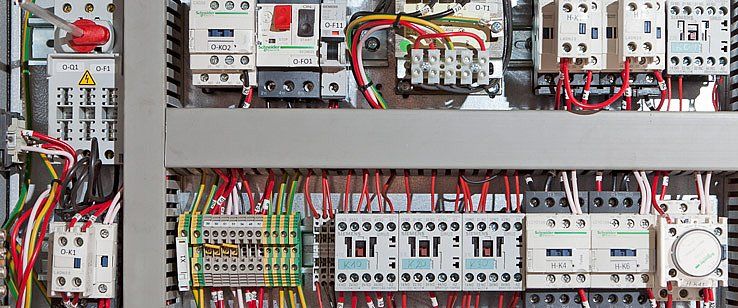

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.