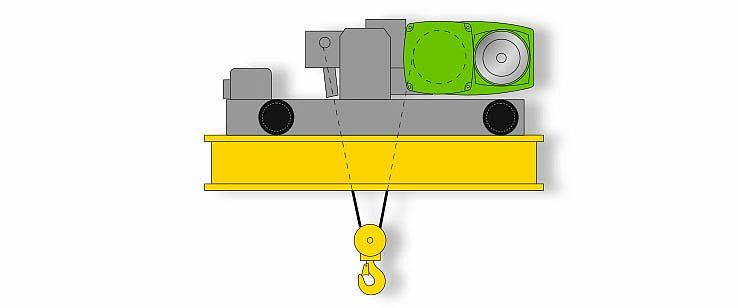

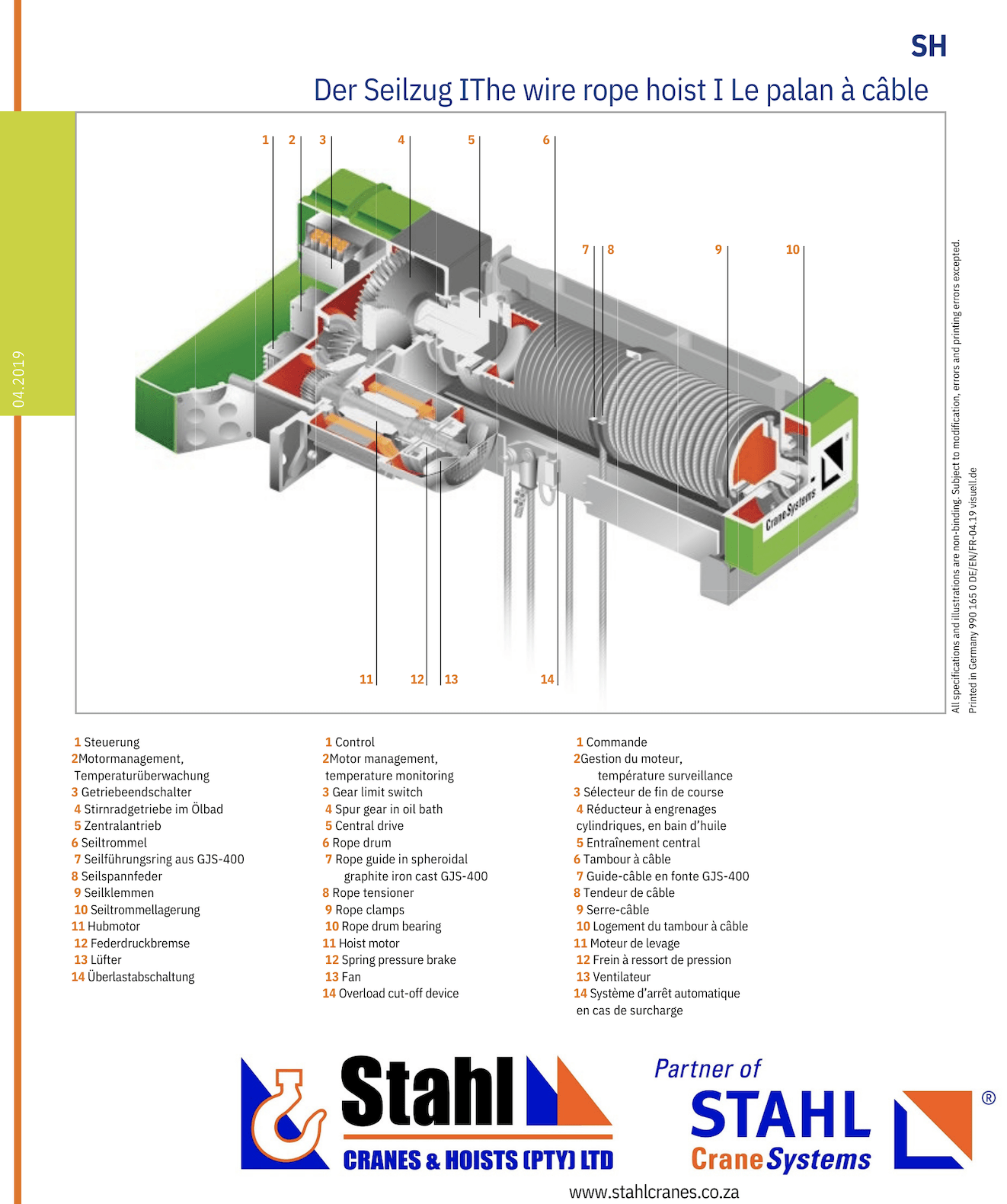

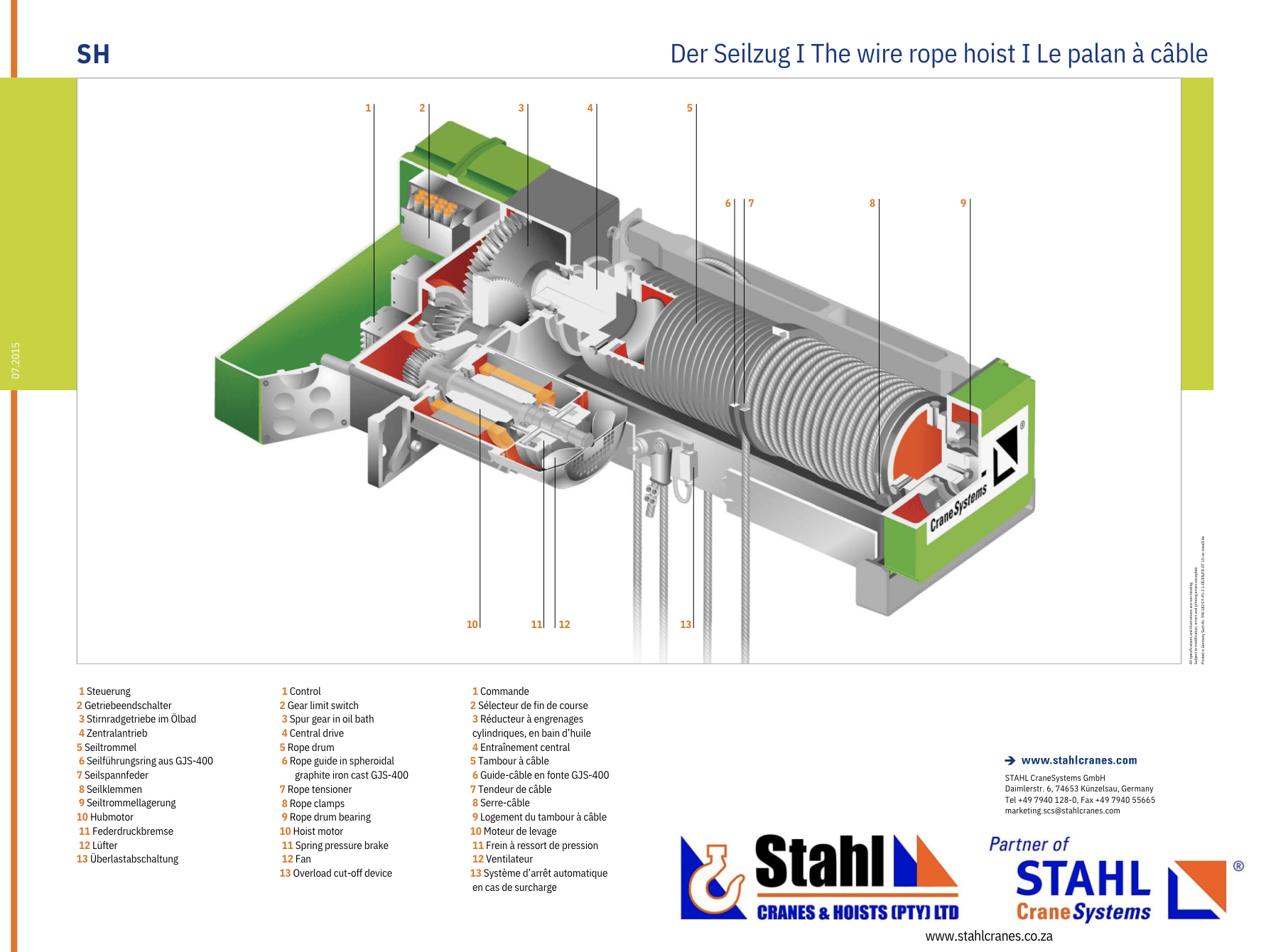

SH Wire Rope Hoist

The Tried And Tested All-Rounder

The

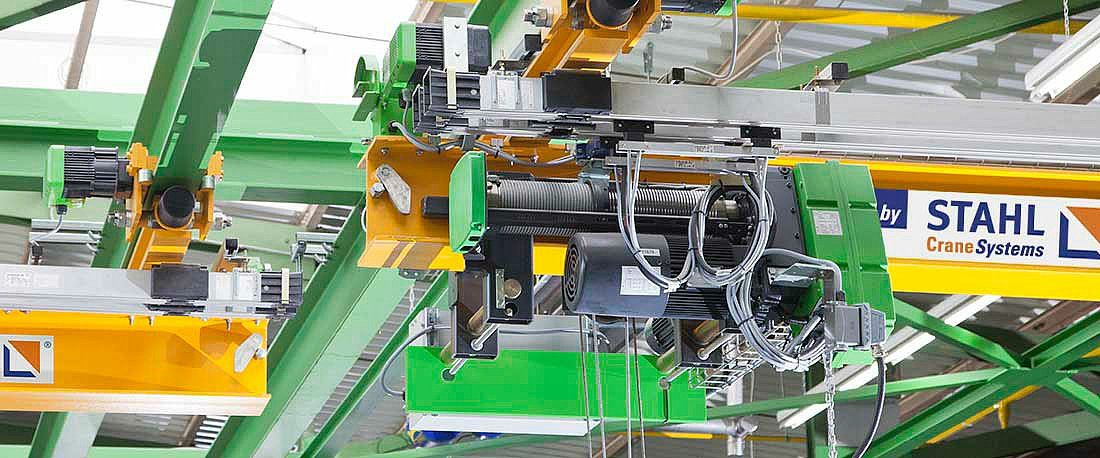

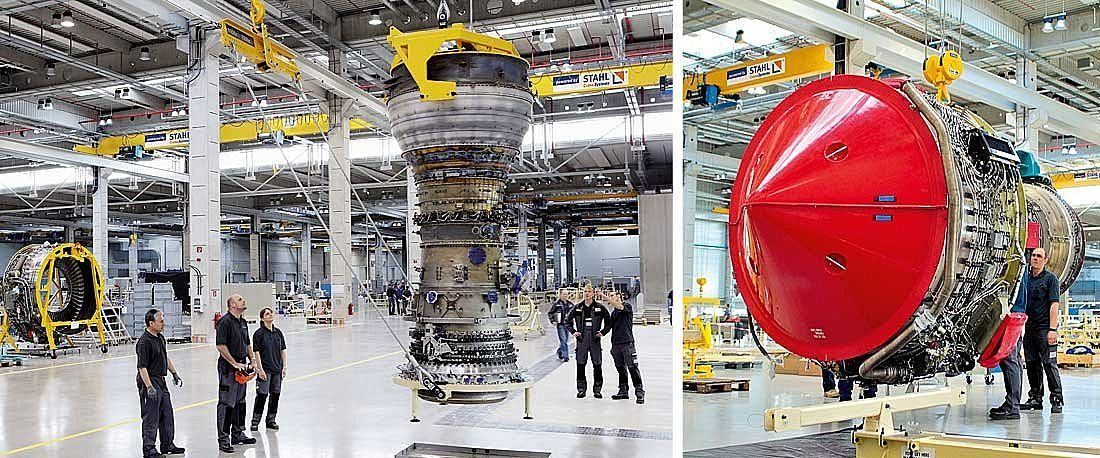

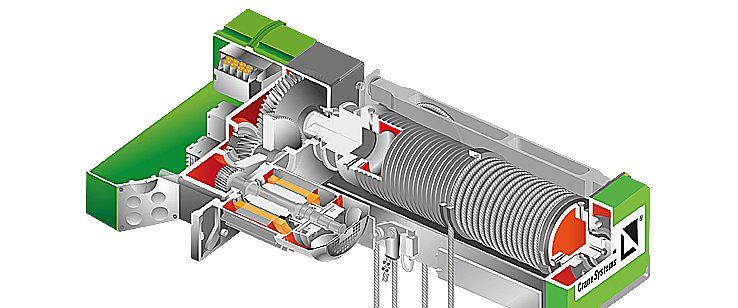

SH wire rope hoist programme is used around the world in many different applications. Compact, strong, particularly maintenance-friendly and an ideal when it comes to combining quality, flexibility and performance.

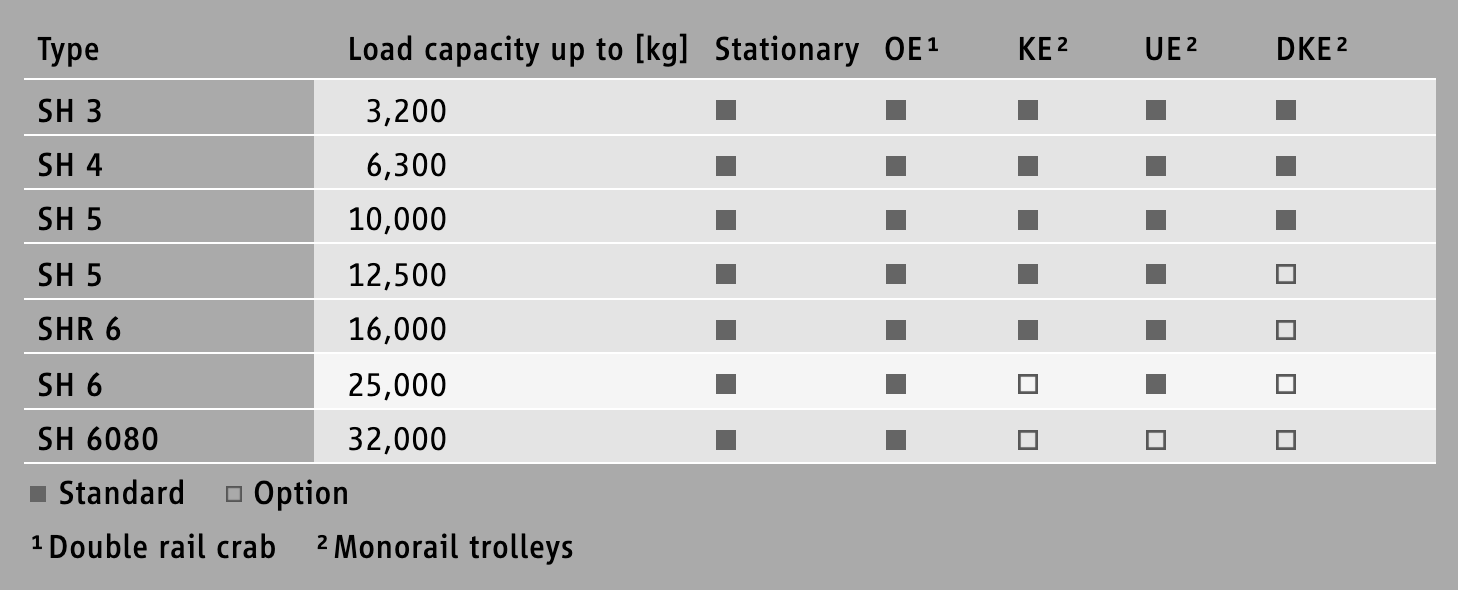

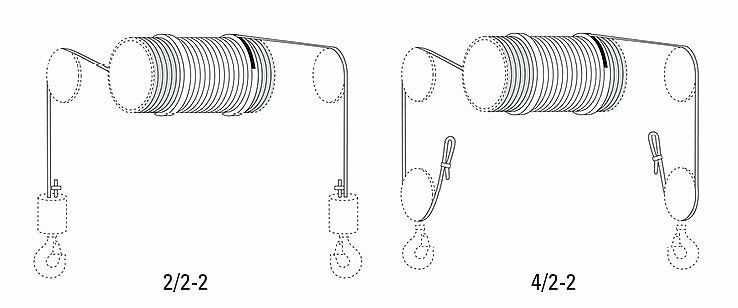

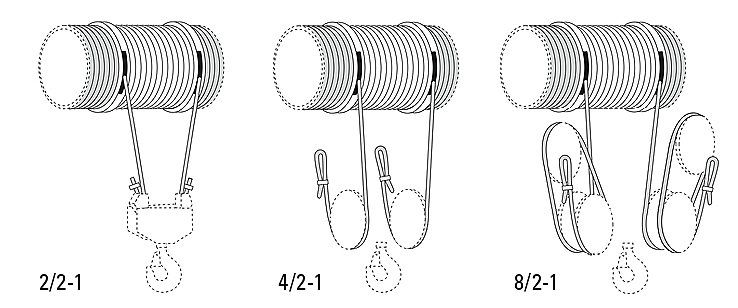

The module system enables almost unlimited combinations of the components. Coming in five sizes with 26 S.W.L. variants, the SH series covers the safe working load range from 500 kg to 25,000 kg. The new SH 6080 wire rope hoist extends the versatile

SH wire rope hoist

range to safe working loads up to 32,000 kg. The

wire rope hoists can be used in stationary applications or together with trolleys in standard cranes, off-standard cranes or systems building.

If wanted, the complete wire rope hoist programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

- 5 sizes, 26 S.W.L. variants

- Stationary version or various trolleys for cranes and systems building

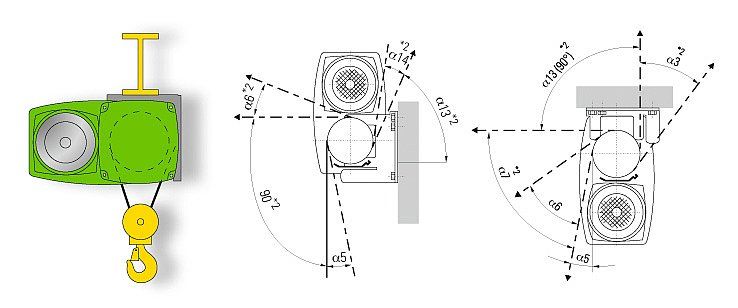

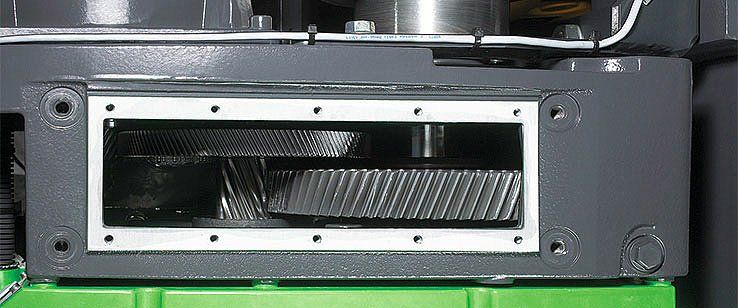

- Compact size thanks to U-shape

- Largely maintenance-free, low wear, long service life according to FEM/ISO standards

- Standard series with two lifting and two travel speeds

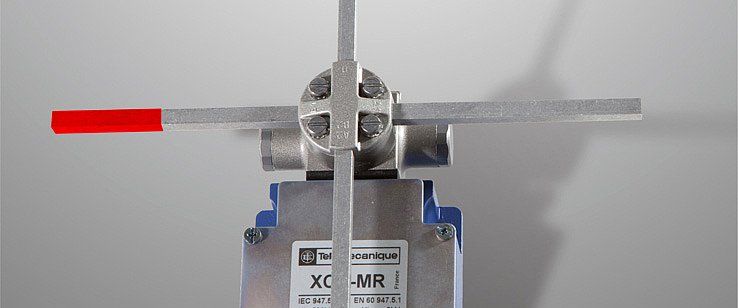

- Particularly soft starting and braking

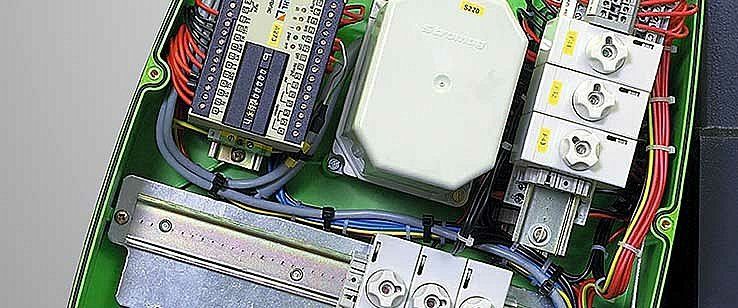

- Standard series with high-quality safety components for improved work safety

- Optionally available in explosion-proof design according to ATEX and IECEx

Technology

Options and features

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.