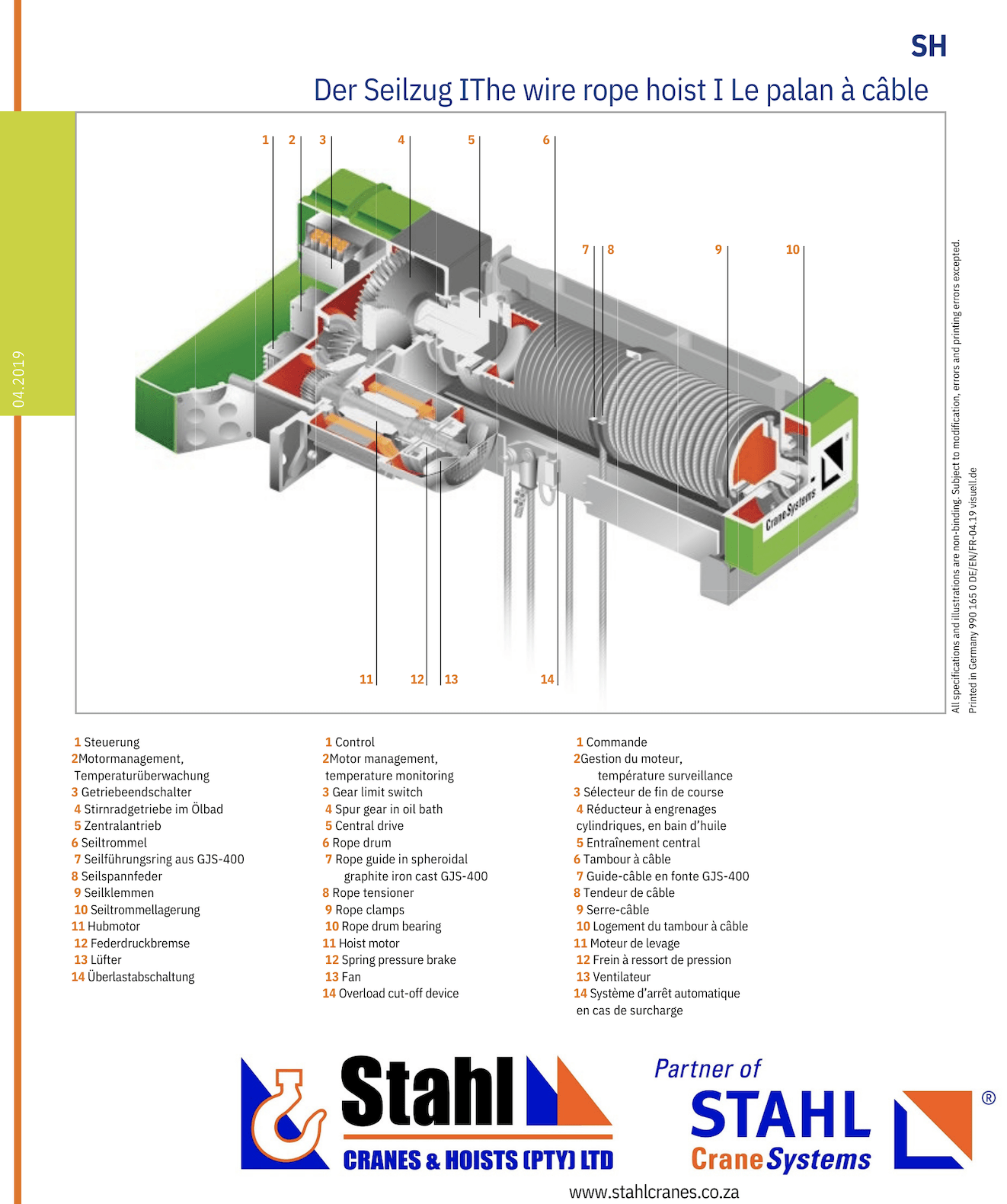

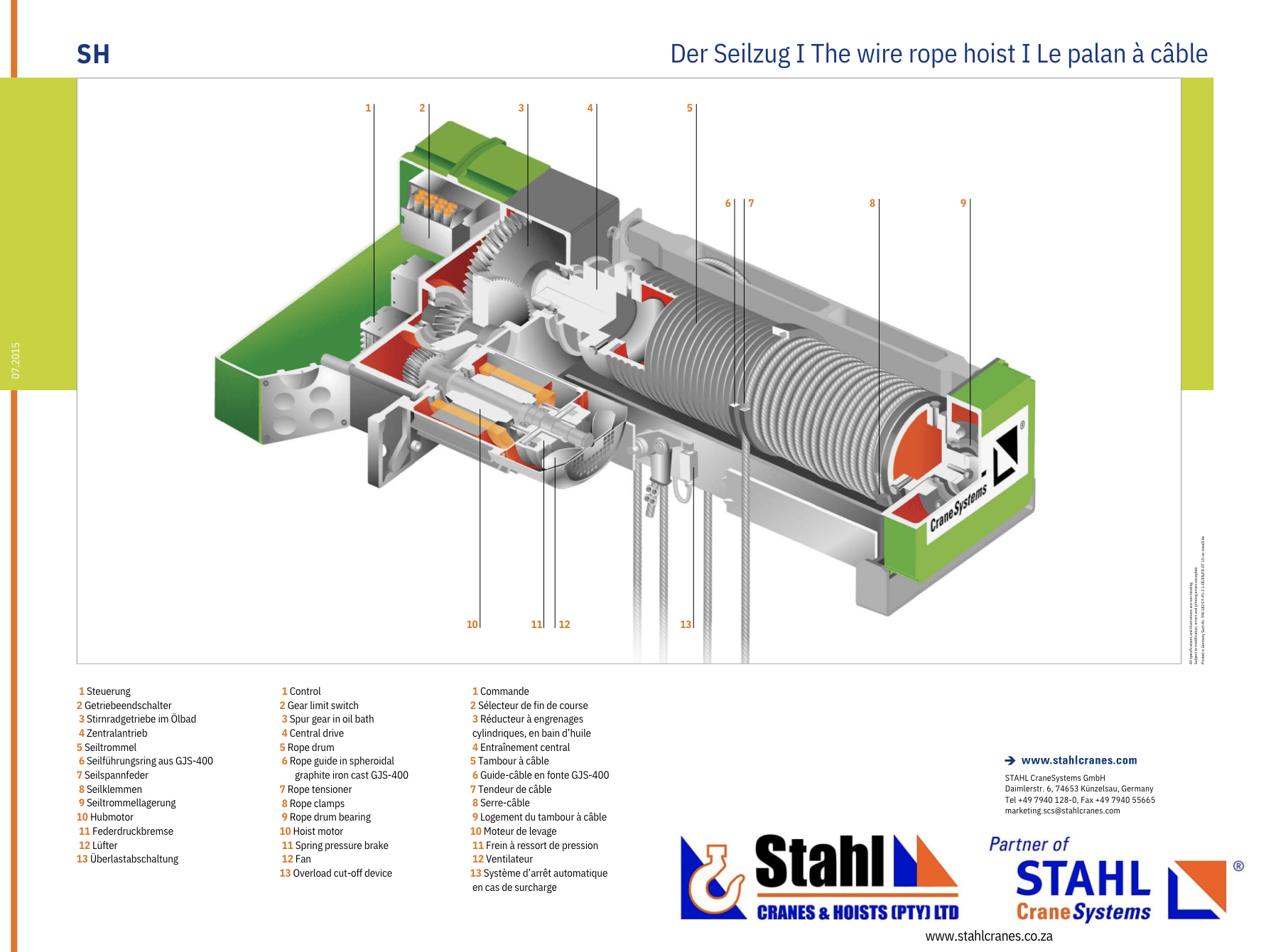

AS 7 Wire Rope Hoist

The Compact Powerhouse

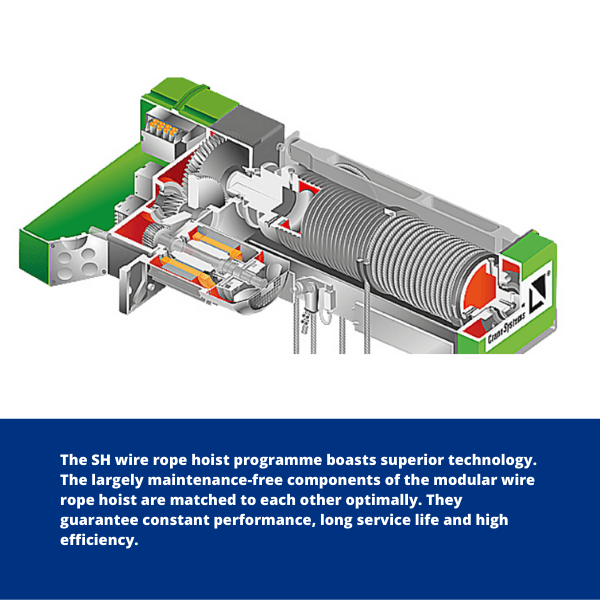

The AS 7 wire rope hoist programme is the innovative classic in hoisting and crane technology worldwide. The modular system enables innumerable combinations of the subassemblies for customised solutions.

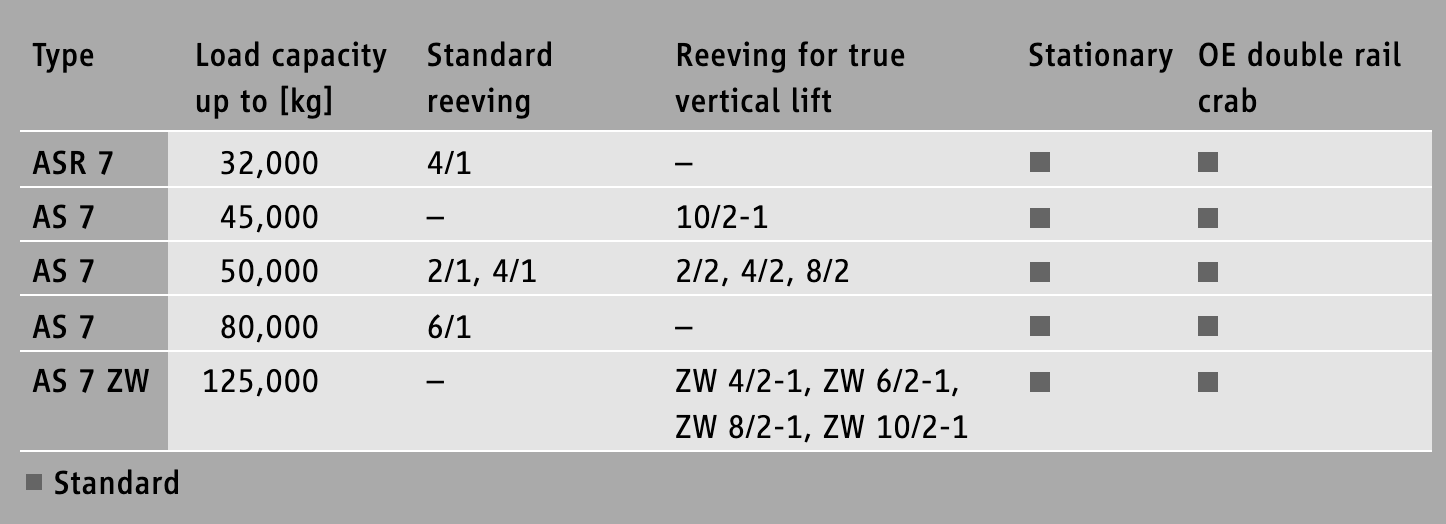

The AS 7 series is designed in two variants for the upper lifting capacity range to 125,000 kg. The ASR 7 wire rope hoist is the reduced version of the tried-and-tested AS 7 wire rope hoist. It is designed for a safe working load range from 20,000 kg to 32,000 kg and closes the gap between efficient use of the SH wire rope hoist programme and the AS 7 wire rope hoist programme.

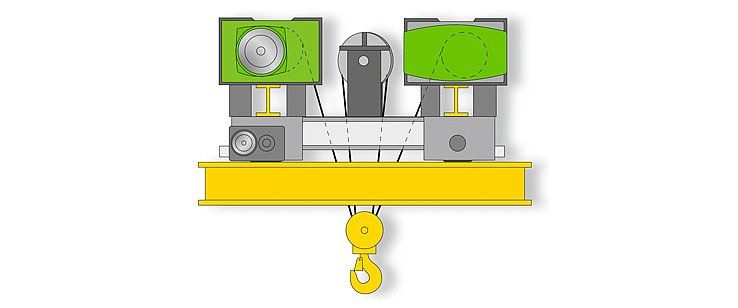

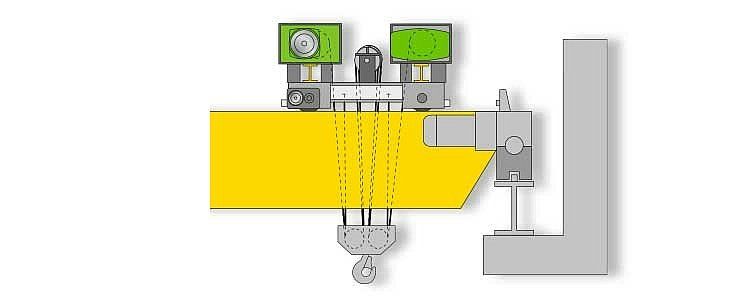

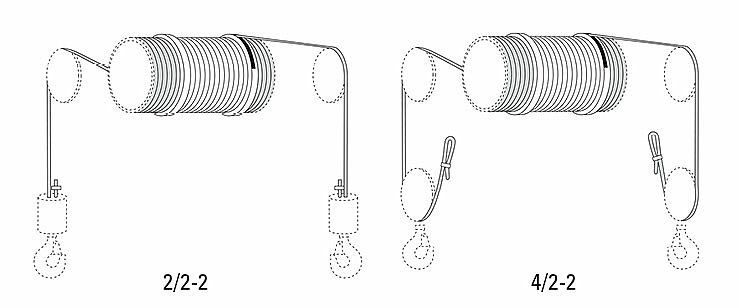

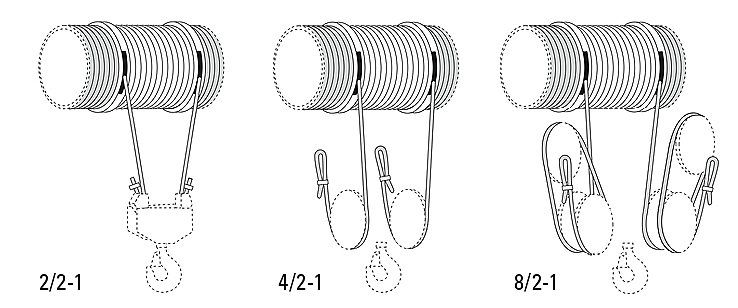

The revised design as twin hoist covers the same fields of application as the AS 7 wire rope hoist, albeit with higher lifting capacities, greater lifting heights and faster lifting movements. One important safety feature of the AS 7 wire rope hoist when designed as twin hoist is its exact positioning of the load. As the rope of the twin hoist runs in opposite directions simultaneously, the load is lifted and lowered without any sideways movement of the hook.

If wanted, the complete wire rope hoist programme is also available in explosion-proof design for Zone 1, Zone 2, Zone 21 or Zone 22.

- Two designs for load capacities up to 125,000 kg

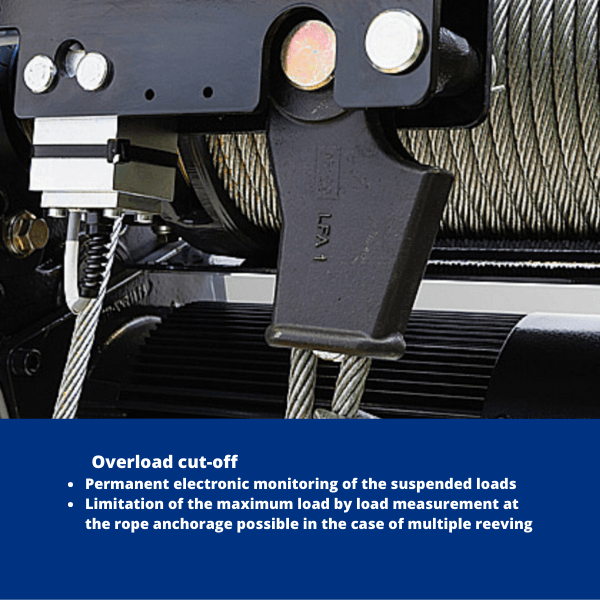

- Reduced-size ASR 7 for a safe working load range from 20,000 kg to 32,000 kg, with larger height of lift, standard with exact load measurement at the rope anchorage (entry-level model)

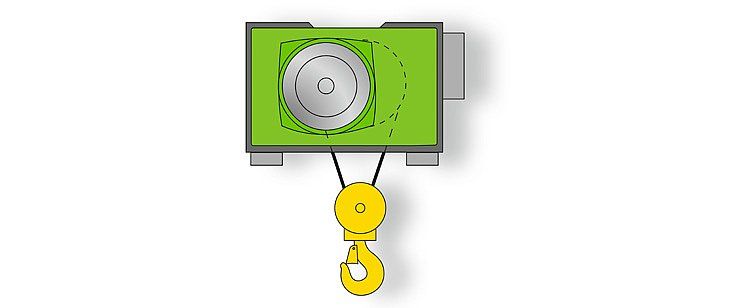

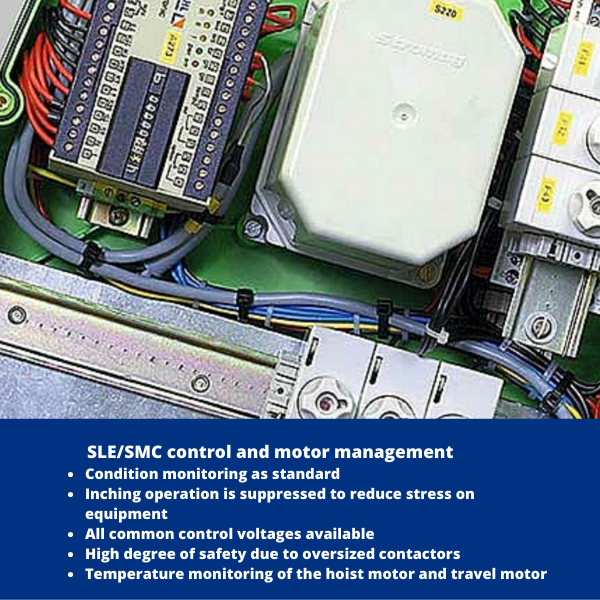

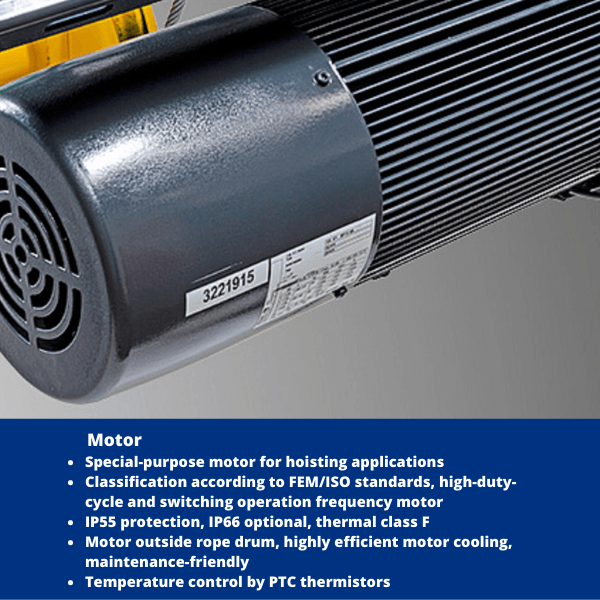

- Innovative drive technology with cylindrical rotor motor with monodisc spring-loaded brake

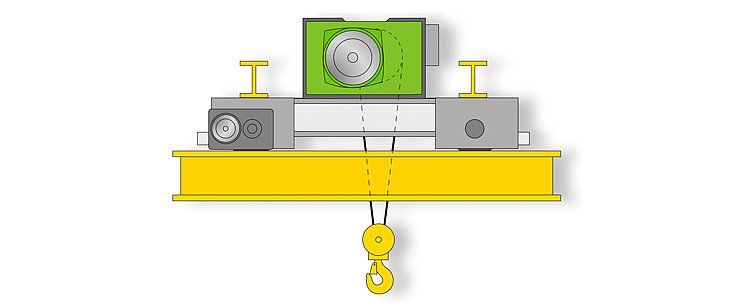

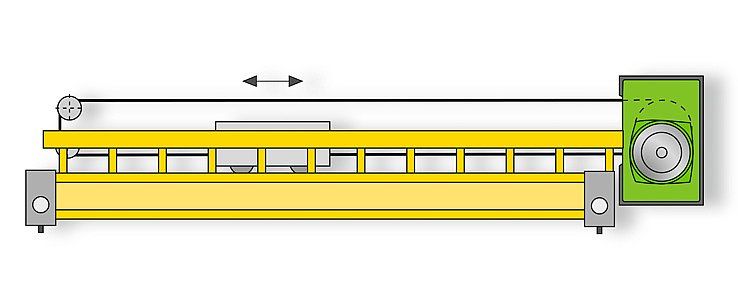

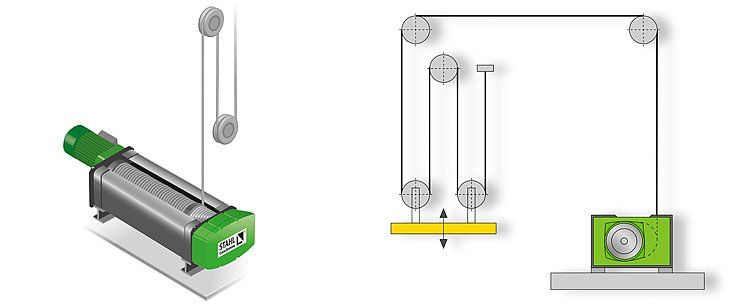

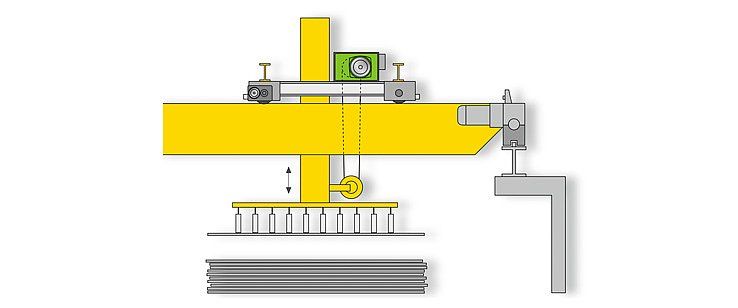

- Stationary version or double rail crab for systems and crane building, optionally available as underslung trolley or articulated trolley

- Compact construction and low approach dimensions

- Higher load capacity, hoisting speed and lifting height as twin hoist

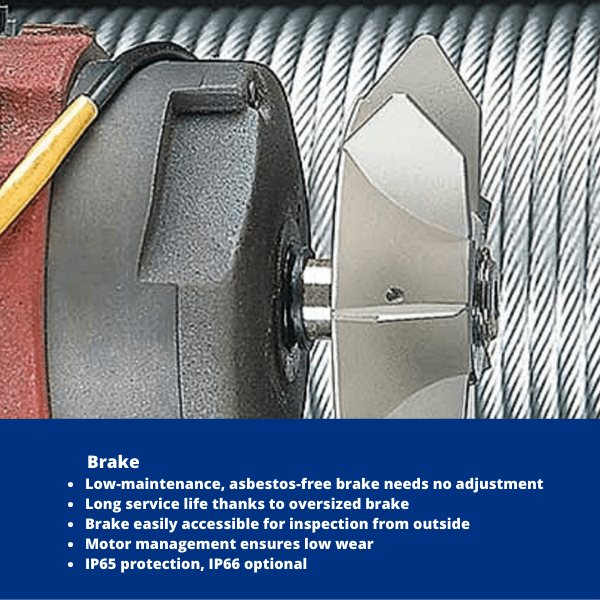

- Largely maintenance-free, low wear, long service life according to FEM/ISO standards

- Optionally available in explosion-proof design according to ATEX, IECEx

Technology

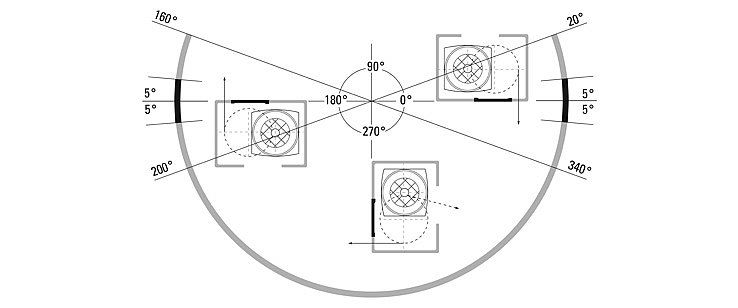

Options and features

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.