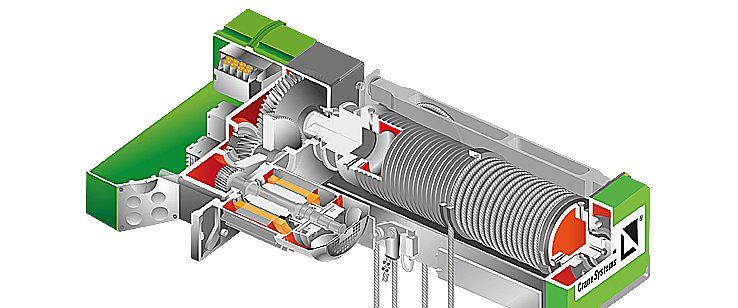

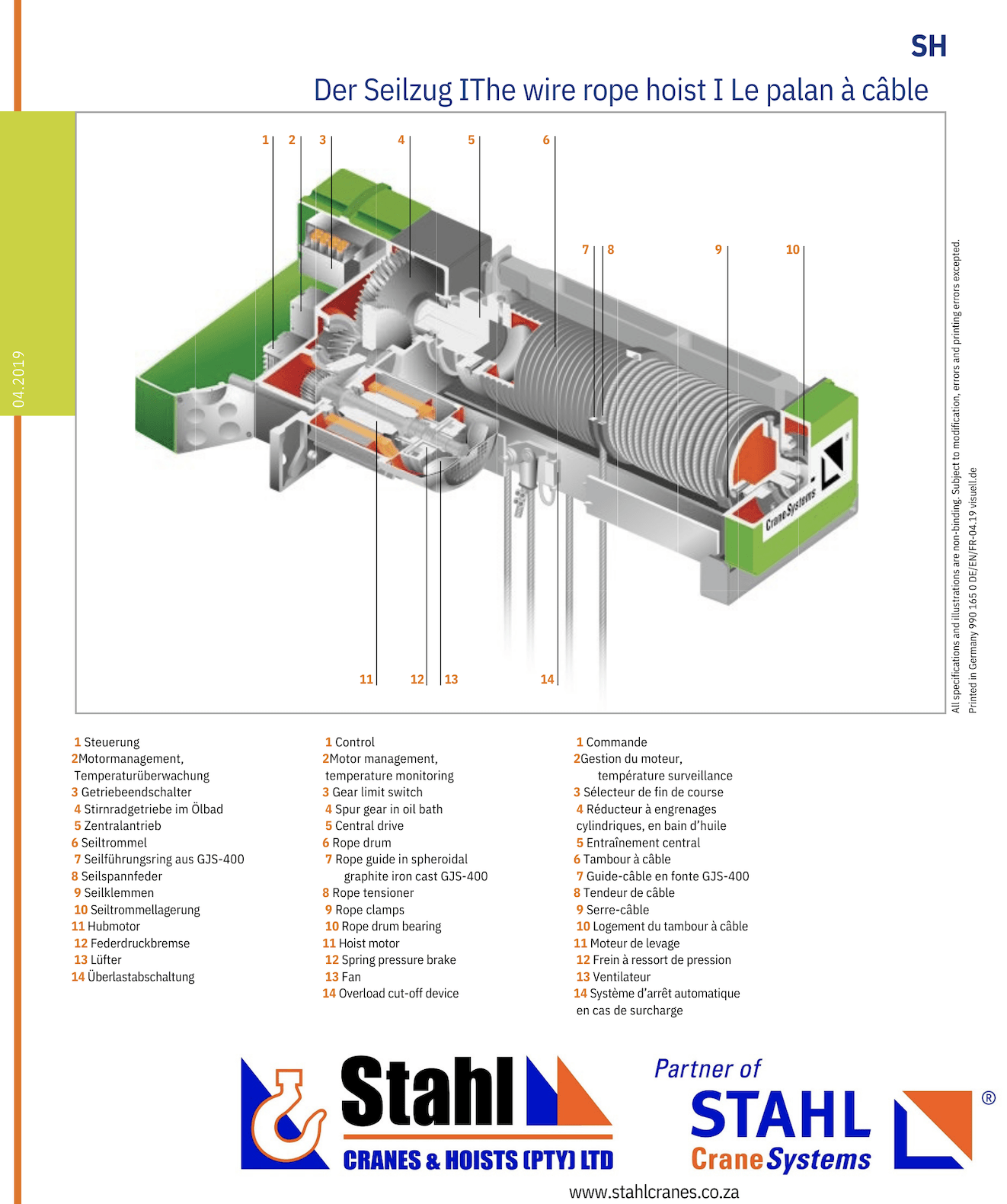

SH 6080 Wire Rope Hoist

Working Loads Up To 32 Tons

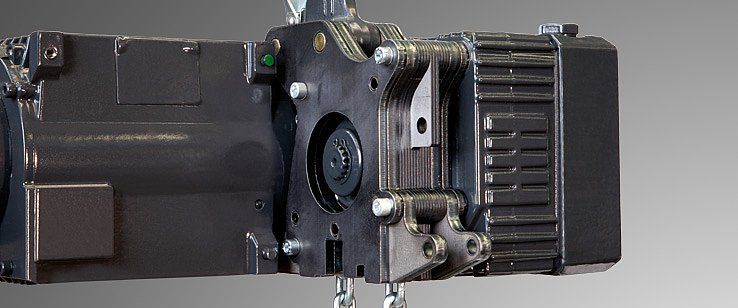

Safe, compact, reliable and low-maintenance: with the SH 6080 Wire Rope Hoist, the advantages of the SH wire rope hoist programme are now also available for safe working loads up to 32,000 kg. Thanks to the proven module system of the SH programme, the strong all-rounder can be adapted to a wide variety of requirements.

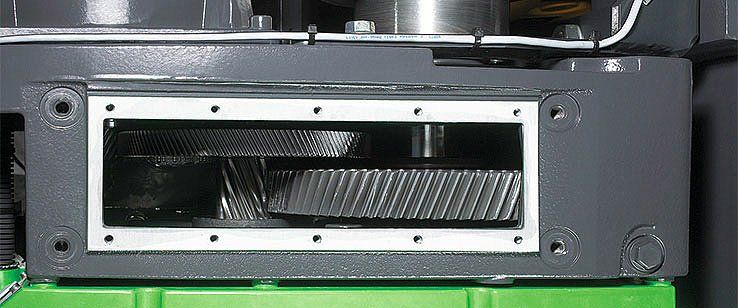

The largely maintenance-free components of the SH range lend the SH 6080 wire rope hoist a high classification in accordance with FEM/ISO standards. The basic version of the SH 6080 wire rope hoist is classified according to ISO M4. For higher speeds, the SH 6080 is available with classification according to ISO M3. For more frequent use at a lower workload, the SH 6080 is available in a higher classification group in each case.

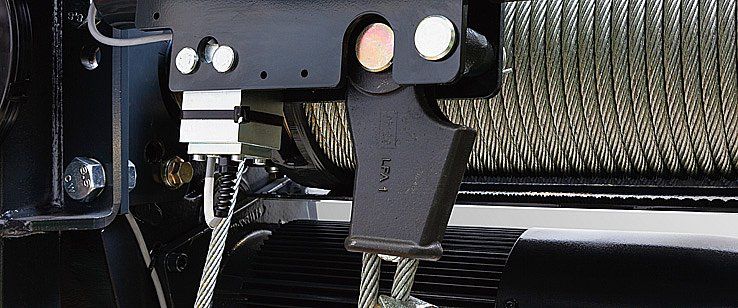

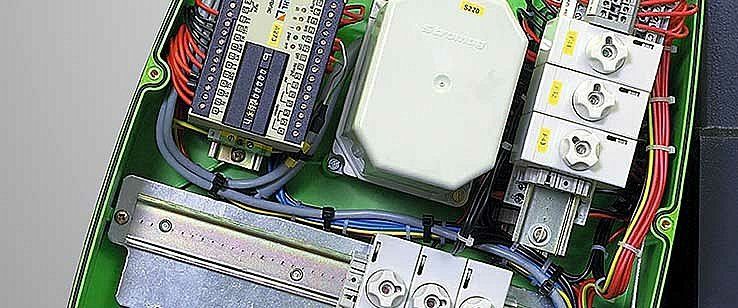

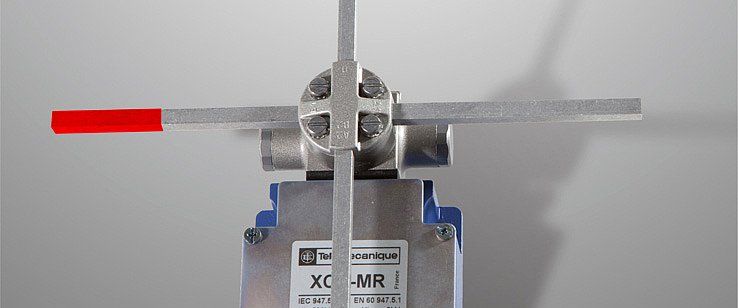

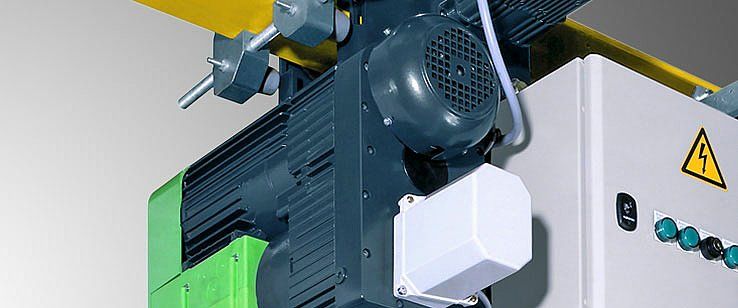

The module system means the SH 6080 wire rope hoist can be adapted to individual customer requirements: for example, all wire rope hoists are available with a lifting height of 6 to 30 metres, and track gauges of 1,400 to 4,000 mm are possible for double-rail crabs. For environments with gases and vapours, the SH 6080 wire rope hoist comes in an explosion-proof version for Zone 2. The strict ATEX directives and IECEx regulations for mechanical and electrical explosion protection are naturally fulfilled. Safety components such as gear-type limit switches, temperature monitoring of the motors and overload safety devices increase work safety.

- Largely maintenance-free, low wear, long service life according to FEM/ISO standards

- Lifting heights from 6 to 30 metres available

- Overhead trolleys available in track gauges from 1,400 to 4,000 mm

- High-quality safety components as standard for improved work safety

- Optionally available in explosion-proof design for Zone 2 according to ATEX and IECEx

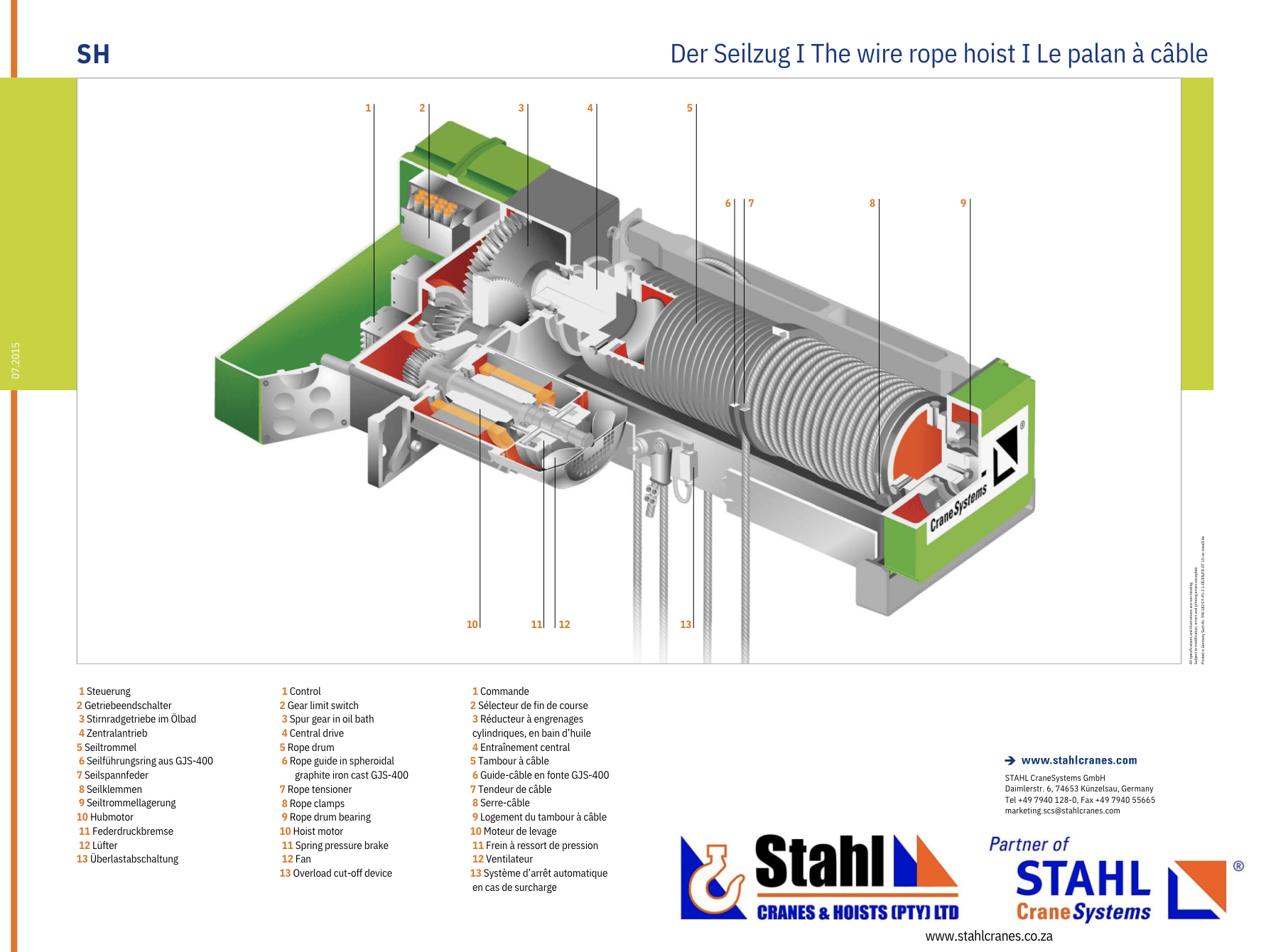

Technology

Options and features

Although they are already first-class in their standard design, you can make the hoists even safer, more economical and more convenient with a range of mechanical, electrical and electronic options. They simultaneously improve performance, prolong service life and make it possible to adapt the hoist individually to specific requirements.

Here are some of the options frequently used.